Rotating Biological Contactors (RBC)

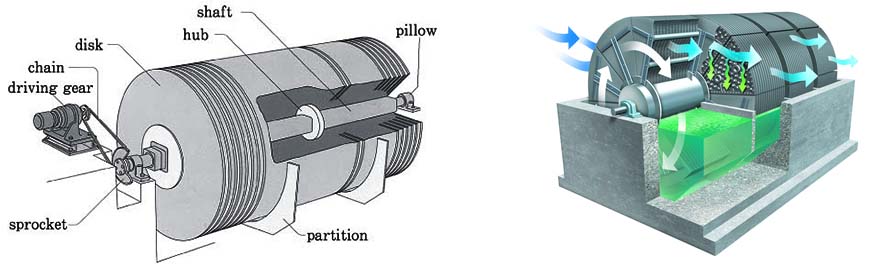

Rotating biological contactors is used in the secondary treatment of wastewater. This technology involves allowing wastewater to come in contact with a biological medium in order to facilitate the removal of contaminants. There are several different designs now available, but in its simplest form a rotary biological contactor (RBC) consists of a series of discs mounted on a shaft which is driven so that the discs rotate at right angles to the flow of settled sewage. The discs are usually made of plastic (polythene, PVC, expanded polystyrene) and are contained in a trough so that about 40 percent of their area is immersed. The discs are arranged in groups or packs with baffles between each group to minimize surging or short-circuiting. With small units the trough is covered and large units are often housed within buildings. This is to reduce the effect of weather on the active bio film which becomes attached to the disc surfaces.

FRBC units are usually installed in a concrete tank so that the surface of the wastewater passing through the tank almost reaches the shaft. This means that about 40% of the total surface area of the disks are always submerged. The shaft continually rotates at 1 to 2 rpm, and a layer of biological growth 2 to 4 mm thick is soon established on the wetted surface of each disk. The biological growth that becomes attached to the disks assimilates the organic materials in the wastewater. Aeration is provided by the rotating action, which exposes the disks to the air after contacting them with the wastewater. Excess biomass is sheared off in the tank, where the rotating action of the disks maintain the solids in suspension. Eventually, the flow of the wastewater carries these solids out of the system and into a clarifier, where they are separated. By arranging several sets of disks in series, it is possible to achieve a high degree of organic removal and nitrification.

The performance of RBC systems depends on the temperature, the concentration of the pollutants, and the rate at which the treatment is expected to proceed.

The oxidation of ammonia is also an important feature in assessing the performance of any biological reactor. The degree of nitrification that is achieved by RBCs is dependent on several factors. Studies have shown that the removal of ammoniacal nitrogen is related to the hydraulic loading rate, and it has been reported that full nitrification can only be achieved when the organic loading rate is less than 5 g BOD/m2/d. Some work has highlighted two aspects of nitrification by RBCs, showing that the process was oxygen limited in summer months and that a good BOD removal was necessary prior to nitrification. Failure to achieve this meant that the amount of disc surface available for colonization by the nitrifying species was significantly restricted.